Power Conditioner Nikola

In times of energy transition, one type of hi-fi equipment is becoming increasingly important: mains filters resp. power conditioners! Fifty years ago, these would not have sold. Back then, our electricity was made by generators. 3000 rpm, perfect sine wave 50 Hz, without harmonics. LED lights, switching power supplies, and solar power did not yet exist.

The load caused by harmonics has become so severe that grid operators are having problems staying within the permitted distortion limits for electricity.

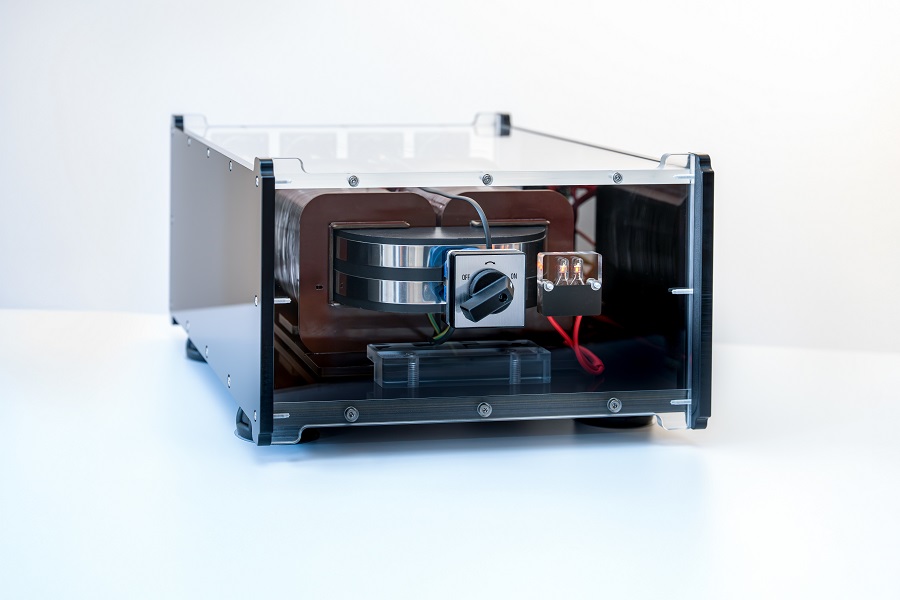

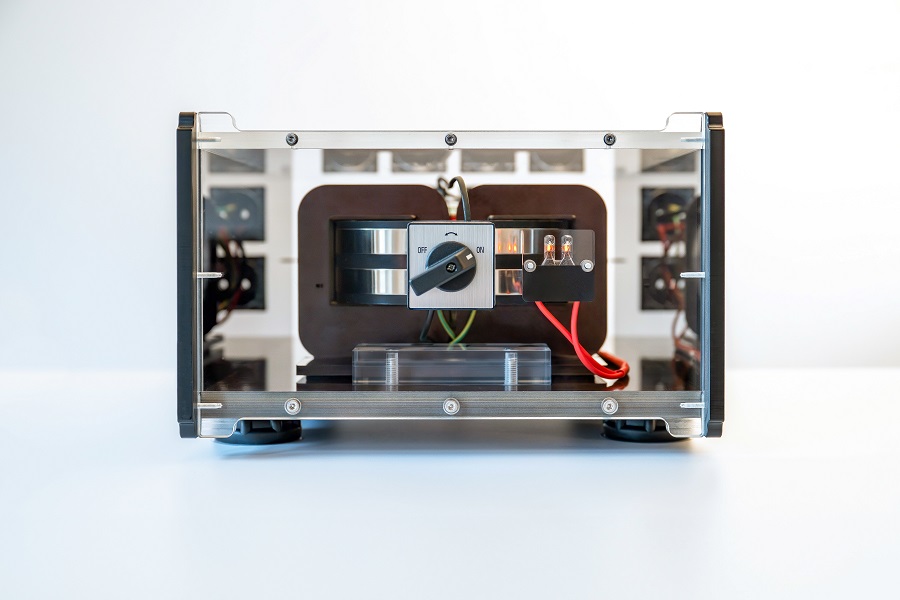

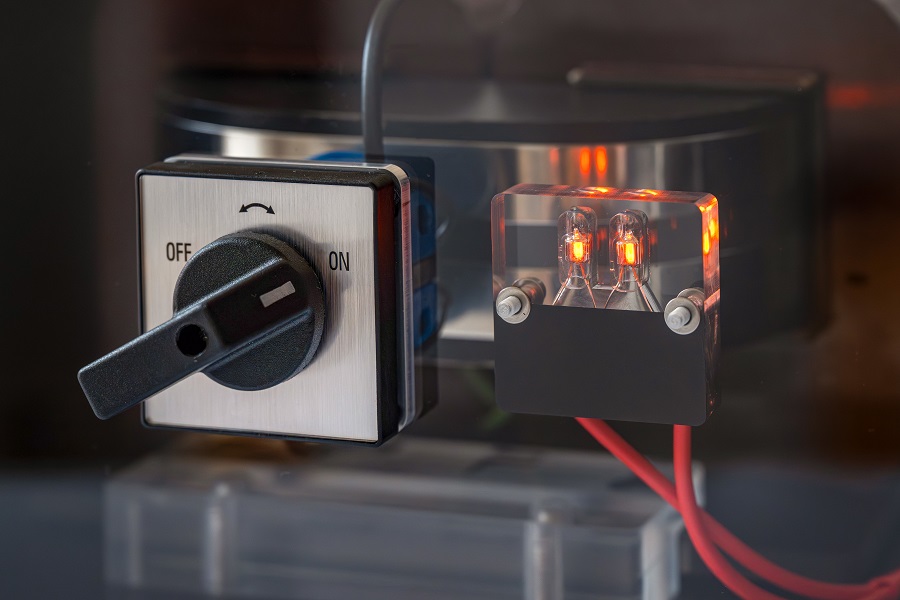

In the Nikola, a central 1:1 symmetrical transformer ensures effective filtering of these disturbances. The power filter is deliberately kept as simple as possible. No bling bling. Only the bare essentials, but these as good as possible. No automatic switch-on, but a two-stage mechanical switch. No LED for operation display, but glow lamps. No cheap input jacks and output sockets, but high-quality ones from Furutech. And definitely no completely nonsensical digital displays for current flow and voltage values.

- input: 230V / 50Hz; IEC C14 with fuse holder 5 x 20mm

- nominal power: 2,000 VA

- idle power consumption: 6VA

- maximum current: 10A

- efficiency: > 96%

- output: 230V / 50Hz; 6 x Schuko

- Furutech input and output sockets

- high-quality housing made of acrylic and pertinax

- dimension: B300 x H200 x T400

- weight: 25kg

- special requests expressly possible

6 Schuko plugs

Technology

Unlike almost all other suppliers, I use a cut tape core as the centrepiece for the symmetrical transformer. I am convinced that a toroidal transformer is not ideally suited for this task.

The Symmetry

One of the biggest advantages of this mains filter is that it balances the voltage at the output. The unbalanced voltage from the wall socket (0V - 230V) is transformed to: 115V - 0V - 115V. All common mode interference coming from the wall socket is thus eliminated at the output of the Nikola. The more ‘symmetrical’ the transformer is designed, the better this cancellation is. This can be clearly seen in the pictures: two coils, each with half the primary and half the secondary winding. The coils are wound as identically (symmetrically!) as possible. This is not possible with a toroidal transformer, as there are no two separate coil bodies.

The Air Gap

In order to prevent high-frequency differential mode interference from being transmitted to the secondary side as much as possible, the stray inductance must be increased and the stray capacitance reduced. This is achieved by means of two air gaps. One is in the iron itself, which is referred to as a ‘cut’ strip core. The other is between the primary and secondary coils. Here, spacers are used to create a large gap between the windings. This is not possible with a toroidal transformer. The first air gap does not exist due to the principle, and I cannot think of a way to implement the second one in a toroidal transformer.

The Shield Winding

There is a shield winding between the primary and secondary windings. These additionally reduce the transmission of high frequencies to the secondary side. The two shields are wound in such a way that the induced voltage cancels itself out.

The Iron Core

The iron in the transformer concentrates the magnetic flux between the primary and secondary coils and forms a closed shape geometrically. It is loaded by the applied alternating voltage, but NOT! by the current flow. No matter how much power is drawn, the iron is always loaded equally. The cut tape core I use comes from the Nuremberg area. It is amazing how complex the manufacture of this single part alone is. And how important it is to obtain a hum-free (iron) core with minimal no-load losses. Direct contact with the manufacturer is very valuable here.

The Copper

The winding window for the copper is derived from the above-mentioned "geometrically closed shape". This means that there is finally plenty of space for the copper. In order to make the best possible use of this space and thus keep ‘copper losses’ to a minimum, I use flat copper or rectangular wire instead of round wire. The wire is also "Made in Germany".

Hysteresis or Magnetisation of the Iron Core

Iron cores cannot absorb an infinite amount of magnetic flux. If the magnetic flux becomes too large, the core becomes saturated. The magnetisation current increases sharply in a non-linear manner. The transmission of a sine wave is then burdened with harmonics. Here, too, the gap in the cut tape core helps by linearizing the hysteresis curve.

In a toroidal core, the winding window mentioned above is extremely small. This is one reason why the iron in this type of core is utilised to the point of saturation. And one reason why I wind the transformer myself. Then I can determine the maximum magnetic flux I want. A good summary of hysteresis can be found here (german only).