Acrylic Glass as a material in High-End Audio

Have you ever removed the cover of your amplifier? Perhaps a tube change was necessary in the preamplifier. Or you have cleaned the lens of your CD player.

Have you ever listened to music without a lid? Yes, I know that's not advisable in the long run. But it sounds better!

What's it about?

Many people think that airborne sound is a problem, which is why such nonsense constellations as "system rack sideways" come about in order to avoid the supposed bass impact in the middle.

But in fact structure-borne sound is the problem. We can perceive a small part of this sound spectrum as vibrations. Every electrical audio circuit reacts to this structure-borne sound. The result is distortions, overlaps and cancellations in the music. Every electrical audio circuit generates structure-borne sound itself! Important "micro-information" that, for example, creates the illusion of "being there" is lost.

Why Acrylic Glass?

Acrylic glass has a very high damping capacity! You already notice it when knocking, there is no rattling! Vibration energy absorbed by the material is converted into heat. And since I replaced parts of the casing – on the spot – with acrylic glass, it works very effectively.

Cast or extruded?

There are two basic manufacturing processes for acrylic sheets: either it is extruded between two rollers and thus brought to the desired thickness. Or it is cast between two parallel plates at the desired distance.

Extruded acrylic has much lower thickness tolerances, which simplifies processing and accuracy of fit.

Cast acrylic has significantly less residual stress, which is why it is more suitable for audio applications. Whenever possible, I use cast acrylic.

What about shielding?

That is the second point why "without cover" sounds better. Shielding of devices and of cables is wrongly evaluated! In fact, I believe that leaving metal out of the vicinity of audio signals is beneficial. Especially when it comes to audio equipment enclosures. The electromagnetic fields generate induction currents in the closed metal enclosure, which in turn generate a magnetic field, which in turn affects the audio signal.

How do I know whether an acrylic cover is worthwhile for my appliance?

Dismantle the bonnet of your unit and listen to music!

How do I get my acrylic bonnet?

You have an audio device that is suitable for an enclosure conversion? Write to me, I will make a suggestion for your device!

Here some Acrylic Glass Projects:

NAT audio Magnetic

A slightly larger preamp ... The deliberate omission of ventilation slots.

- lid made of 6 mm thick acrylic glass

- cast low-stress acrylic glass

- dampens unwanted vibrations / resonances

- prevents induction currents in the enclosure

Symphonic Line RG14

Beautiful German craftsmanship from the Rolf Gemein. This project is a good example of how I am saving more and more on the ventilation slots. Or positioning them so that they are most effective. Not because I'm too lazy to mill, but because the devices should be as ‘airtight’ as possible to keep dust out. Incidentally, acrylic lets infrared radiation through very well. Many appliances would manage (to their advantage) without any ventilation slots at all.

- lid made of 5 and 8 mm thick acrylic glass

- cast low-stress acrylic glass

- dampens unwanted vibrations / resonances

- prevents induction currents in the enclosure

Acrylic Lid for the CD104/204/304

Spectral DMC30SV

Many years ago, this was my dream preamp. But the price ...

- made of 5 mm thick acrylic glass

- cast low-stress acrylic glass

- dampens unwanted vibrations / resonances

- prevents induction currents in the enclosure

Keces P8

Keces has been producing linear power supplies for all kinds of applications for a long time. In my opinion, switching power supplies have no place in high-end audio.

- made of 3 mm thick acrylic glass

- cast low-stress acrylic glass

- dampens unwanted vibrations / resonances

- prevents induction currents in the enclosure

Denafrips Gaia

A digital to digital converter (DDC). Okay, you never stop learning. Until now, I assumed that such a conversion takes place in the DAC.

- made of 6 mm thick acrylic glass

- cast low-stress acrylic glass

- dampens unwanted vibrations / resonances

- prevents induction currents in the enclosure

Thivan Labs P10 and Transformer

You read good things about Thivan Labs. And at a very pleasant price. Packaging is debatable, which is why I replaced the steel lid with an acrylic lid that sounds and looks better. What is not debatable, however, is cabling. It seems that my customer is not the only one who has (had) a hum issue with the step-up transformer. So we took an afternoon and went searching with the oscilloscope. At some point the bottom plate of the transformer housing was off and we got wide-eyed: everything is connected to the outside earth terminals. All "ground" signals of the four RCA sockets and the metal housing. Phew, how can you voluntarily give up the balanced signal of the pick-up??

- all made of 8 mm thick acrylic glass

- cast low-stress acrylic glass

- KLEI Classic Harmony RCA sockets on the transformer

- the metallic housings of the transformers and all ground signals

can be connected via a luster terminal as desired

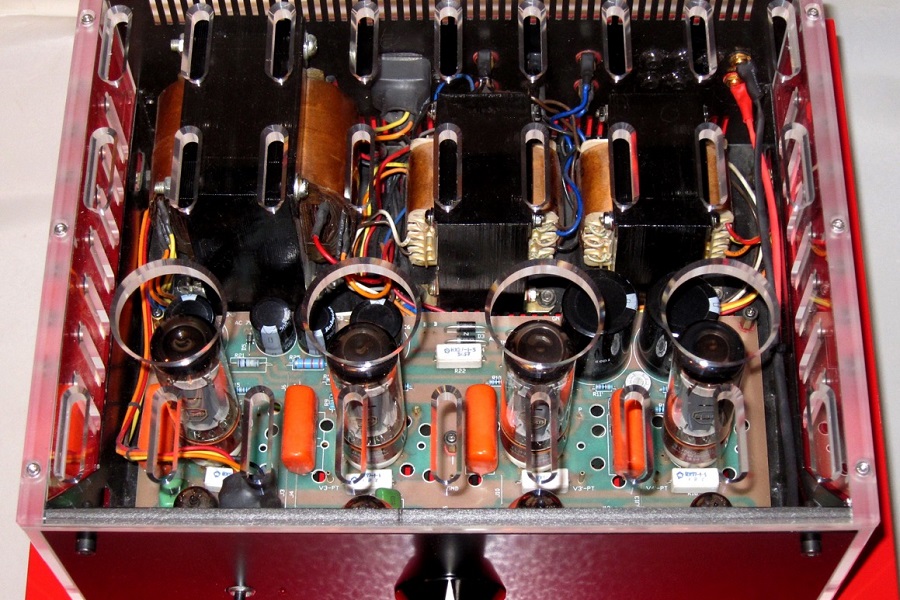

sw1x DAC

Slawa Roschkow's DACs look quite colourful inside. However, he has not recycled the leftover box, but listens to components and mixes them together to create an emotional and captivating sound image. My customer had already removed the cover months ago on my tip. Now, finally, the acrylic cover is on and the DAC sounds even better.

- lid made of 8 mm thick acrylic glass

- side walls made of 3 mm thick acrylic glass

- cast low-stress acrylic glass

- also available in other colours

- easy replacement of the original sheet metal cover

- dampens unwanted vibrations / resonances

- prevents induction currents in the enclosure

MFE Tube One

This is a rather minimalist design and only suitable for child- and pet-free households. This is because the side walls are missing.

- lid made of 8 mm thick acrylic glass

- cast low-stress acrylic glass

- grey coloured, also available in other colours

- easy replacement of the original sheet metal cover

- dampens unwanted vibrations / resonances

- prevents induction currents in the enclosure

Hoer-Wege Phono-MC Evo V2

A friend of mine bought Stephan Horwege's circuit boards, but wanted an even fancier case than the ones offered by Mr Horwege. Well, after many hours of juggling thoughts and drawing and milling, the acrylic glass case was finished. It consists of a solid base plate made of 14mm thick acrylic. The back and side walls are 8mm thick. Lid and front are 10mm each. The milled front was supposed to be the inside first. But it looked so noble that the plan was changed.

- base plate made of 14 mm thick acrylic glass

- cast low-stress acrylic glass

- also available in other colours

- completely drilled and milled for the Phono-MC Evo V2

- including Solidcoreaudio Isolation Feet

- with shielding plate for the phono section on request

- WxDxH = 410x380x70

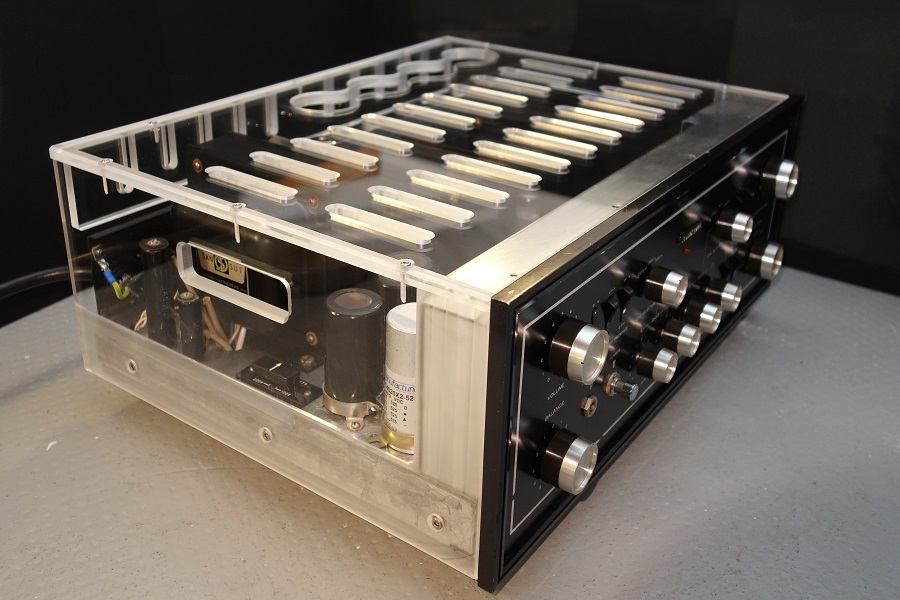

Rowen Absolute Mono

Very beautiful compact monobloc amp from Switzerland. The part of the new cabinet that protrudes in height is drawn flush with the front.

Here you can easily imagine how the magnetic field of the toroidal transformer generates induction currents in the closed metal housing. The comparison before / after is particularly striking with this unit.

- lid, sidewalls made of 10 mm thick transparent acrylic glass

- cast low-stress acrylic glass

- also available in "frost" or other colours

- easy replacement of the original sheet metal cover

- dampens unwanted vibrations / resonances

- prevents induction currents in the enclosure

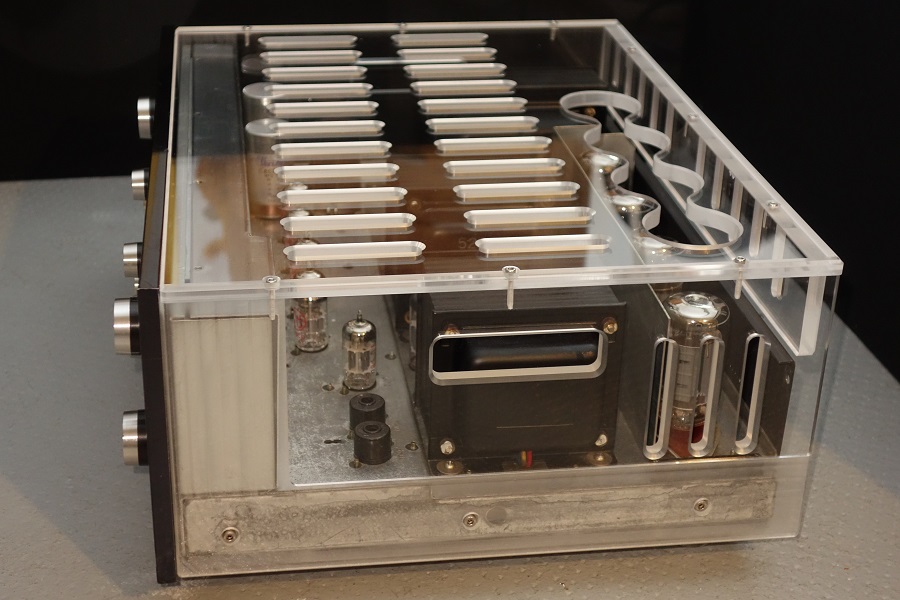

Lua 4040 C

Obviously, I wasn't the first to lay a hand on this device.

This unit also sounds much better with acrylic glass lid than with the original metal lid.

- lid, sidewalls made of 10 mm thick transparent acrylic glass

- cast low-stress acrylic glass

- also available in "frost" or other colour

- easy replacement of the original sheet metal cover

- dampens unwanted vibrations / resonances

Sansui AU111

A design classic from the 60s. Sansui no longer produces them today, but the units will probably find lovers forever.

Tubes benefit particularly from acrylic, as they react more strongly to microphonic effects than transistors. Large openings have been created in the area of the end-stage tubes, the heat is safely dissipated. The unit even stays cooler than with the original lid.

Not visible in the pictures is the new acrylic base plate in which the isolation feet (plate system) has been integrated.

- lid, sidewalls and backwall made of 10 mm thick transparent acrylic glass

- optional base plate with integrated isolation feet

- cast low-stress acrylic glass

- also available in "frost" or other colour

- easy replacement of the original sheet metal cover

- dampens unwanted vibrations / resonances

and backwall

integrated isolation feet

audio research LS17SE

The LS17SE preamplifier has been providing me with loyal service in my work for 5 years. Some time ago I had already taken off the lid and listened to "open" music. Simply sounds better. In the long run this of course is not a good idea, because the anode voltage is almost 300 volts. So a different cover was needed. Acrylic glass is an obvious choice and is widely used in the audio sector as housing material. Now I know why! If this is already a fantastic preamplifier per se, the acrylic cover catapults it very high up.

- lid and sidewalls made of 10 mm thick transparent acrylic glass

- cast low-stress acrylic glass

- also available in "frost" or other colour

- easy replacement of the original sheet metal cover

- dampens unwanted vibrations / resonances

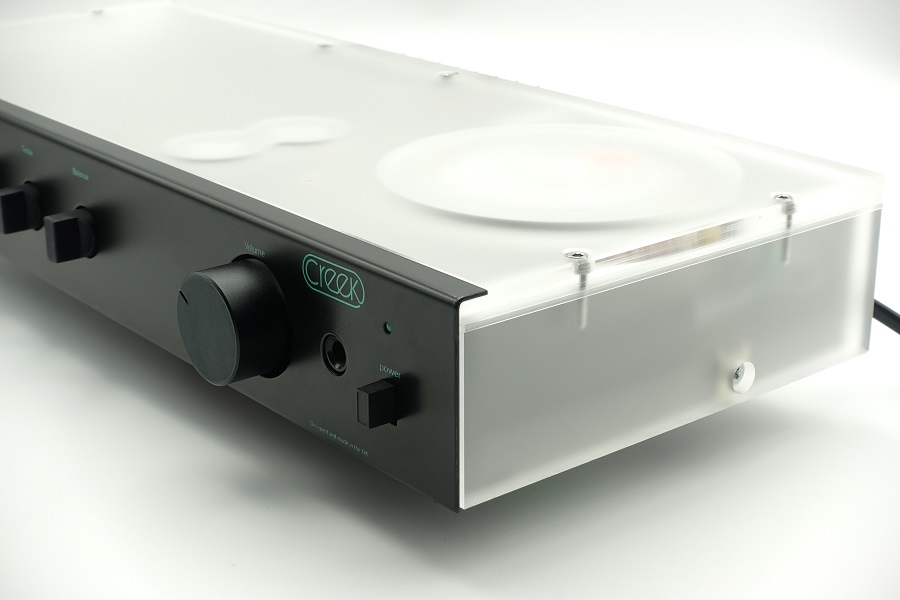

creek 4040

Did Mike Creek realise back then that a metal lid on an amplifier doesn't necessarily sound better? At least I can't imagine that the original wooden lid was chosen for cost reasons.

However the acrylic glass lid enhances this amplifier treasure not only visually, but also sonically. A nice example of the effect of the acrylic is the screw connection of the heat sink to the lid. If the screws are not tightened, the cooling fins slowly fade out after hitting them. With the screws tightened, this resonance is clearly damped.

- lid and side walls made of 8 mm thick acrylic glass "frost"

- also available in transparent or other colour

- einfacher Austausch des originalen Holzdeckels

- easy replacement of the original sheet metal cover

- dampens unwanted vibrations / resonances

- Heat sink firmly screwed to the cover

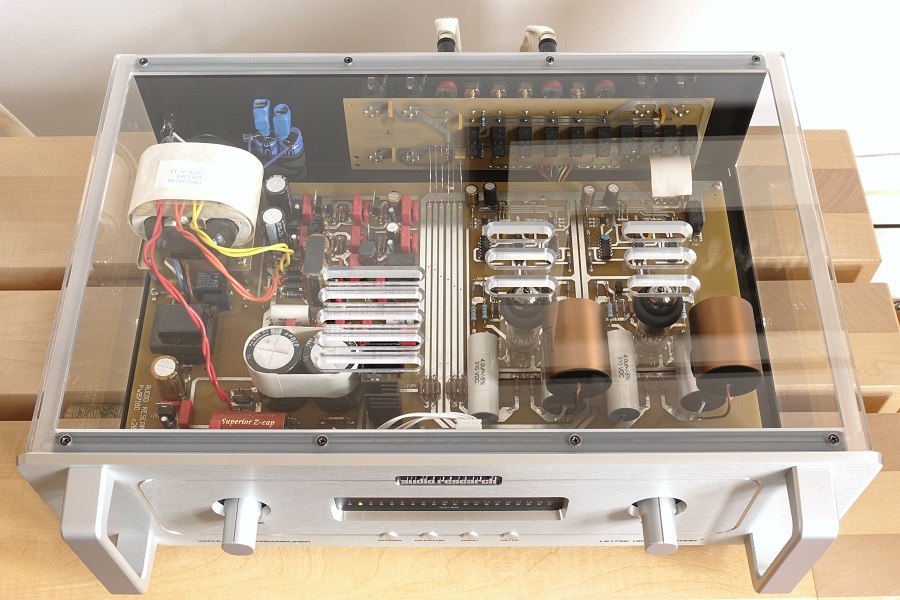

Acoustic Signature P723

There are probably not 10 of these power amplifiers in the world. What a monster of power and at the same time so sensitive.

- Base and lid made of 20mm acrylic glass

- power supply board mounted on 8mm acrylic glass